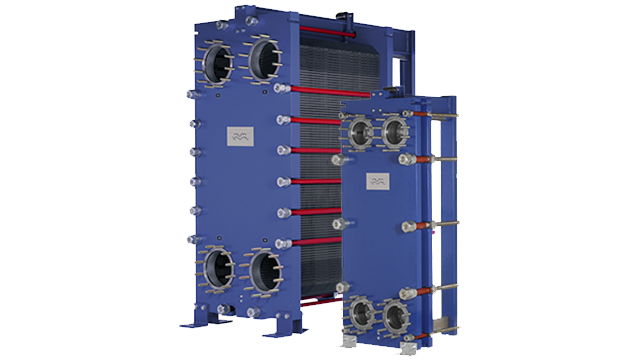

WideGap

Alfa Laval WideGap gasketed plate-and-frame heat exchangers are suitable for fibrous fluids and for fluids containing coarse particles. Typical applications for Alfa Laval WideGap heat exchangers are sugar, bioethanol and pulp and paper processes. Depending on the duty, WideGap heat exchangers can be configured either with wide-wide or wide-narrow channels. This makes the units suitable for heating, cooling and interchanging duties.

Tailor-made

Alfa Laval WideGap is tailor-made for handling fibrous fluids and for fluids containing coarse particles. The smooth port design ensures that fibres don’t get stuck at the entrance.

Equipped with well-designed features, Alfa Laval WideGap heat exchangers are easy to maintain and have a long service life. Some of the features available include:

- ClipGrip™ gasket – a glue free gasket with superior alignment that ensures a perfect seal and trouble-free maintenance.

- Glued gasket – a two-component, oven-cured epoxy glue keeps the gasket in place during any possible cleaning condition.

Additionally, the pressure plate roller, the bearing boxes on tightening bolts, and the 5 point alignment system with reinforced hangers make opening and closing the heat exchanger quick and easy without the need for heavy tools or the risk of damaging the plates.

Alfa Laval WideGap is quick and easy to modify if process parameters change. Our team’s expertise and the availability of parts bring you peace of mind.

Peace of mind

Alfa Laval global service network is never far away.

Features and benefits

- Maximum uptime for fouling applications

- High energy efficiency

- Flexible configuration

- High serviceability

- Access to Alfa Laval’s global service network

Kaip tai veikia

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger. The WideGap heat exchanger is tailor-made to handle fibrous fluids, highly viscous fluids, and fluids containing coarse particles. Because of the plate pattern and pressing depth design, these fluids flow easily through the heat exchanger.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

The WideGap heat exchanger can be configured in many ways. The channels can have either a wide/wide gap or a wide/narrow gap with different channel gaps. WideGap heat exchangers are usually configured as multi-pass in order to ensure enough turbulence.

Liquid/Liquid GPHE

Steam Heater GPHE

>