BaseLine

"Alfa Laval BaseLine" - tai konkurencingas plokščių ir karkaso šilumokaičių su tarpikliais asortimentas, skirtas paprastesnėms pieno, maisto, gėrimų, farmacijos ir kitoms higienos bei komunalinėms reikmėms.

Dizainas ir konstrukcija leidžia derinti plokštes ir medžiagas - platus tarpiklio medžiagos pasirinkimas

- Patogus aptarnavimas - FDA reikalavimus atitinkančios tarpinės, kad būtų lengva atidaryti, tikrinti ir valyti

- Atsparumas užsiteršimui ir šiluminis efektyvumas dėl spaudimo gylio ir ševroninių raštų bei įvairių gofravimų

- Lankstus - pasikeitus proceso parametrams, šilumos perdavimo plotą galima keisti pridedant ar išimant plokštes arba derinant skirtingas plokštes

- Tinka daugiasekciniams plokšteliniams pasterizavimo šilumokaičiams

Pareigų optimizavimas: BaseLine plokšteliniai ir rėminiai šilumokaičiai yra keturių skirtingų dydžių (Base 3, 6, 10 ir 11) ir veikia su įvairių tipų plokštelėmis, kad būtų užtikrintas optimalus našumas jūsų pieno, maisto ar gėrimų gamyboje.

Žr. "Alfa Laval Frontline", skirtą sudėtingesnėms higienos reikmėms

Plokščių tipai skirtingiems higienos poreikiams

"BaseLine" ir "M Line" plokšteliniams šilumokaičiams su tarpikliais siūlomi du skirtingi plokštelių tipai:

- "Chevron" tipo plokštelių raštas užtikrina gerą produkto pasiskirstymą ir aukštą šiluminį efektyvumą ir yra naudojamas maisto, pieno, gėrimų ir farmacijos pramonėje.

-

"Gemini" dvigubų sienelių plokštelės užtikrina visiškai atsparią maišymui konstrukciją. Ją sudaro dvi tarpusavyje suspaustos plokštelės, kurios apsaugo nuo kryžminio skysčių užteršimo, jei skysčiai prasisunkia pro plokšteles.

Šokolado rašto pasiskirstymo plotas užtikrina, kad skysčiai tolygiai pasiskirstytų visoje plokštelėje ir būtų išvengta sustingusių zonų, kurios gali užsiteršti.

Kaip tai veikia

Tarp plokštelių suformuoti kanalai, o kampinės angos išdėstytos taip, kad abi terpės tekėtų pakaitomis. Šiluma perduodama per plokštelę tarp kanalų, kur priešpriešinis srautas padeda pasiekti didžiausią įmanomą efektyvumą. Plokščių bangavimas užtikrina praėjimą tarp plokščių, palaiko kiekvieną plokštę prie gretimos ir sustiprina turbulenciją, todėl šilumos perdavimas yra efektyvus. Mūsų šilumos projektavimo inžinieriai padės jums suprojektuoti ir parinkti modelį bei konfigūraciją, atitinkančią jūsų taikymo poreikius, užtikrinant didžiausią šiluminį našumą ir sumažinant slėgio kritimą.

Alfa Laval higieniniai skysčių/skysčių GPHE

Alfa Laval daugiasekcinis pasterizatorius GPHE

Higieninis daugiasekcinis GPHE

Funkcijos

Reguliuojamos kojelės

Guolių dėžė

Prijungimo plokštės ritinėlis

Pailgosios veržlės

Fiksuota varžto galvutė

Rakto skylutės varžto anga

Spyruoklinė poveržlė

Slėgio plokštės ritinėlis

Varžto dangtelio priveržimas

Higieniškų plokštelinių šilumokaičių su tarpikliais asortimento dalis

Dešimt svarbiausių patarimų - Higieniniai plokšteliniai tarpikliniai šilumokaičiai

Pateikiame keletą patarimų ir aptarnavimo vaizdo įrašų, kuriuose matysite, kaip galite palaikyti savo higieninių tarpiklinių plokštelinių šilumokaičių nepriekaištingą būklę.

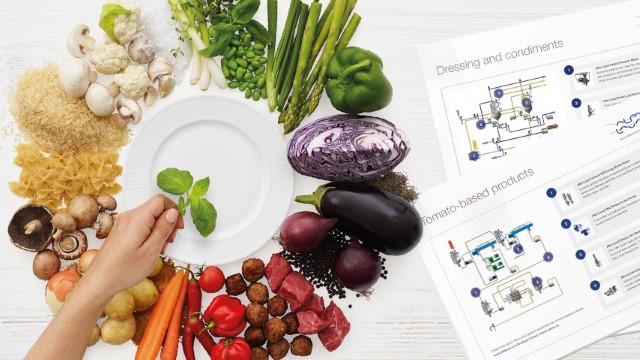

Maisto logika

"Alfa Laval" higieninė įranga suderina aukštą našumą ir švelnų valdymą, kad būtų išsaugotos jautrios sudedamosios dalys ir neatsiliktų nuo maisto pramonės tendencijų. Įranga padeda spręsti keturis pagrindinius uždavinius: tiekti maisto produktus vartotojams už konkurencingą kainą, maksimaliai išnaudoti žaliavas, mažinti atliekų ir išmetamųjų teršalų kiekį bei tiekti saugius ir higieniškus maisto produktus.

Reikalauti naujų standartų

Pristatome moderniausius pasaulyje tarpiklinius plokštelinius šilumokaičius. Sužinokite, kaip mūsų naujos kartos plokščių su tarpikliais šilumokaičių linija užtikrins didesnį efektyvumą, patikimumą ir geresnį aptarnavimą.