UV or EC? Achieving the lowest OPEX in ballast water treatment

When you choose wisely from the beginning, you also save money over time. Chemical-free UV treatment with Alfa Laval PureBallast 3 lets you avoid the neutralization costs of electrochlorination (EC), which add up quickly if your vessel engages in short trade. What’s more, it saves energy in cooler waters and lets you keep your vessel trimmed for fuel efficiency. Find out why UV ballast water treatment keeps operating costs lower.

- Avoid costly neutralization chemicals

- Keep energy consumption low at any temperature

- Maintain vessel trim and fuel efficiency

- Ensure maximum operating flexibility

Costs are lower without neutralization chemicals

Treating ballast water without chemicals is better for crews and the environment, but the OPEX savings are biggest difference with chemical-free UV treatment. If your vessel engages in short trade (a week or less between ports), just the annual chemical costs for electrochlorination (EC) can be equal to three years of PureBallast 3 operation – power consumption included.

TRO levels have to come down

Neutralization of total residual oxidants (TRO) is the reason for EC’s high chemical costs. The chlorine disinfectant must be eliminated before you can discharge the ballast water. The less time there is for TRO to degrade naturally, the more neutralization chemicals you need to add. So, if you can’t afford holding time, you pay for chemicals instead.

Stocking matters too

Naturally, there are other costs to chemicals than the chemicals themselves. It takes space and crew time to stock them on board. With a chemical-free UV ballast water treatment system, both factors disappear.

Want a deeper understanding?

To learn more about the issues of time and chemicals, be sure to download our short guide to holding time.

Low energy costs at any temperature

Power consumption means less for the OPEX of ballast water treatment systems than the use of TRO neutralization chemicals. Nevertheless, UV solutions like PureBallast 3 have an energy advantage over electrochlorination (EC) systems: UV treatment is effective at any water temperature, whereas EC systems lose efficiency as the temperature drops. With UV, you avoid extra heaters that mean more CAPEX, but also added energy costs when sailing in colder waters.

Power management saves you more

What matters for UV treatment efficiency is the water’s UV transmittance (UVT), which varies from port to port. You’ll want a UV system that can handle low water clarity, and which offers effective power management. PureBallast 3 efficiently handles UVT as low as 42% in IMO-regulated waters, and it reduces power consumption anywhere the UVT is higher.

Want a deeper understanding?

To learn more about the issues of temperature and UVT, be sure to download our short guide to salinity, temperature and UVT.

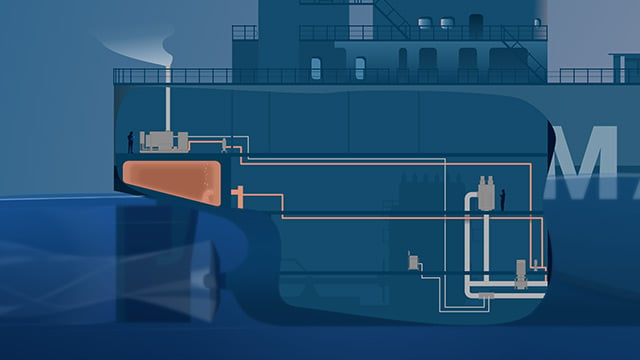

Use your APT as intended – for vessel trim

Ideally, your ballast water treatment system shouldn’t affect your vessel’s operations. UV ballast water treatment systems like PureBallast 3 impact nothing but the ballast water, but electrochlorination (EC) systems can increase your fuel costs by 2–5% – and reduce cargo capacity if your vessel is a tanker.

That’s because electrochlorination depends on water salinity. If you sail in waters with lower salt content, you’ll need to add saline water, which is usually stored in the aft peak tank (APT). When the APT is used for storage, you can’t use it to optimize vessel trim or carry cargo. So you spend more money and may lose potential income.

Want a deeper understanding?

To learn more about the issue of salinity, be sure to download our short guide to salinity, temperature and UVT.

Make sure you have freedom to sail

What matters most for your OPEX is being able to trade as needed. Type approval isn’t the same as compliance, and all ballast water treatment systems have limits defined by their type approval certificates. Use Compliance Navigator to compare the performance of UV and electrochlorination (EC) systems on your own trade routes.

Shipowner insights into OPEX

For WALLENIUS SOL, UV ballast water treatment with PureBallast 3 was the clear choice for its new LNG-fuelled Mega RoRo vessels. Lower OPEX was a decisive factor, especially in the brackish and colder waters where the company sails.

“OPEX is, of course, very important,” says Ragnar Johansson, Managing Director, who notes that electrochlorination (EC) systems lose efficiency as the water temperature drops. “The purchase price is one thing, but the system will cost money every day. So energy consumption is extremely important.”

Contact us to discuss the choice of UV or EC

Your choice of technology may be the most important one you make in ballast water management. We’d be happy to discuss it with you, in brief or in depth.