Yeast propagation plant

Alfa Laval Yeast Propagation Plant is engineered for yeast propagation under sterile conditions within the brewing industry for the purpose of renewing the yeast supply. The flexible design of the yeast propagation plant enables propagation of different strains of yeast as needed. The single (or multi) vessel plant requires initial inoculation with laboratory-propagated yeast culture (using the Alfa Laval SB Carlsberg Flask).

A reliable and safe process for uninfected, freshly propagated yeast

- Enables maximum yeast vitality and viability due to unique process design

- Built for yeast propagation brewing – all process valves and fittings uniquely designed for yeast propagation

- Agitators ensure gentle homogenization

- Easy and reliable operation thanks to standard design and well proven technology

Yeast propagation process

When CIP and steam sterilization are completed, the yeast propagation vessel is filled with hot or cold wort. Wort is then sterilized by the heating jacket on the cone and then cooled down by the cooling jacket on the cylindrical part. Before inoculation, the wort is aerated with sterile air. The vessel is then inoculated with pure yeast culture (from a Carlsberg Flask) under sterile and aseptic conditions.

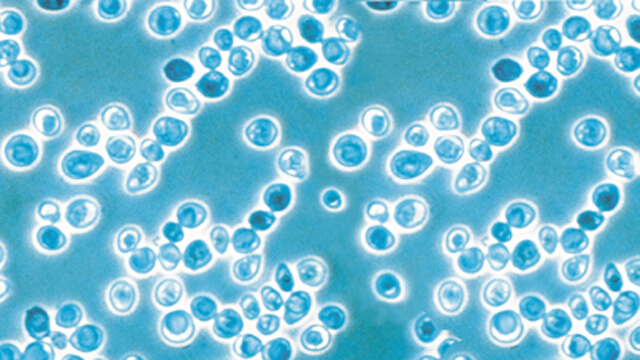

During yeast propagation, the temperature is maintained at a set level, and the propagating yeast is aerated according to the requirements of the particular strain. When the yeast has reached the required cell concentration, it is pitched into an intermediate fermenter or directly into the yeast fermentation tank.

Cleaning

Before operation or transport all lines are flushed with water and sterilized steam. The yeast propagation system is cleaned via an integrated or external CIP plant.

Installation

The yeast propagation equipment is pre-assembled and dry tested before dispatch. Then, it is marked in our workshop for easy re-assembly at the brewery according to the enclosed manuals

Maintenance

The valves should be checked, and gaskets changed at regular intervals. In addition, the filter insert is to be replaced at least every two years.

Learn more

You can read more about the efficiency, practicality and technical details of propagating yeast for brewing with Alfa Laval’s Yeast Propagation Systems by downloading the brochure.